Buying scooter wheels

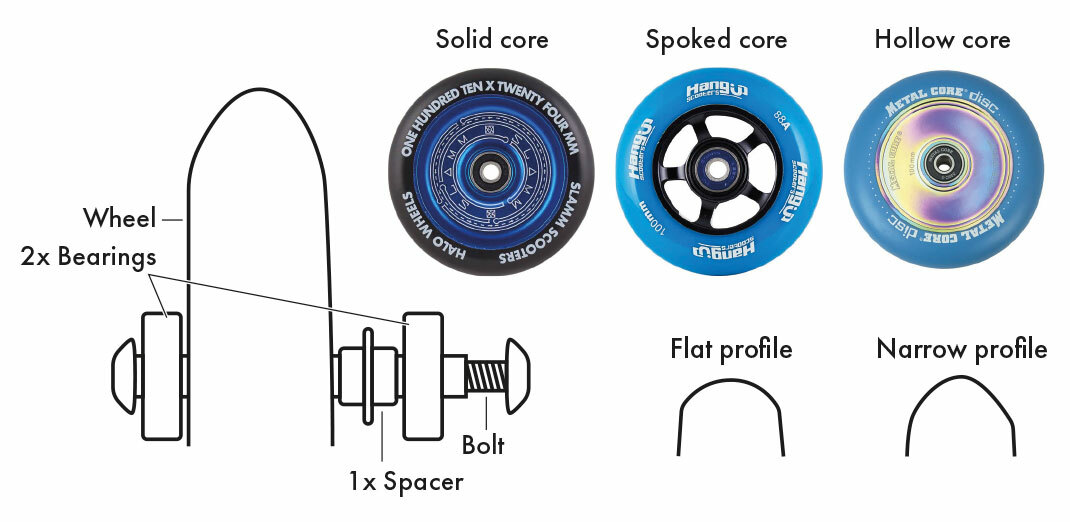

Every wheel needs 2x bearings and 1x spacer to function.

Wheels are made of different materials, dimensions, hardness, profiles and different cores.

The illustration tells you what is what.

Cores

- Solid core. Massive core for maximum durability.

- Spoked core. Core with holes and cutouts. Makes a lightweight wheel, but also weaker!

- Hollow core. Hollow inside for lightweight, while still maintaining strength. (Not as strong as solid core)

- Plastic core, Not pictured. Plastic cores do not last long and are a bit flexible.

- Honeycomb core, Not pictured, The same principle as the hollow core, but is even lighter thanks to the perforated holes.

Profiles

- Flat profile (a flat profile that gives strength to the rubber and maximum grip)

- Narrow profile (a narrow profile gives you speed)

Hardness

- The durometer scale goes from 0-100a, where 100a is the hardest. Most scooter wheels are 85a.

- Hard wheels last longer, they are more slippery but are also faster!

- Soft wheels wear down faster but have a good grip, great for parks and indoor use.

- Not all manufacturers inform the wheel hardness, then just try it out.

Mounting bearings into the wheel

- It can be difficult to install bearings into a wheel, we have made a video guide for Mounting bearings into a scooter wheel with a metal core here.

Hints

- Always install bearings so that they are 100% aligned with the centre, otherwise both bearings and wheel centre will be damaged.

- Hammering the wheel or bearings with a hammer during installation will void the warranty and right to claim the item.

- Some wheels with a flat profile will not fit in front forks with a pointed profile.

- Always replace your wheels when worn down, for your own safety but also, so you don't destroy the Flex fender brake!

Claim or wear and tear?

Wheels that are produced for the purpose of making tricks, are often exposed to extreme pressure and have therefore, like all other wheels, limited durability.

Every time you practice spinning tricks like a tail whip or a 360, you land sideways, which is hard on the wheels. If this is repeated many times, the material of the wheel can break or parts of it can be torn off.

So how do you decide, whether it can go as a claim case or if it is broken due to usage?

Flat spots

If you brake very hard on the scooter and lock the brake so that the wheel is pressed against the asphalt, while driving, blocking the rear wheel, it can create a so-called "flat spots". A flat spot gives a straight line in the bend of the wheel and makes the ride bumpy.

A "flat spot" is not a production error and will not be covered under the standard warranty. The reason for a "flat spot" is (wrong) usage of the scooter, as no wheels are harder than asphalt.

Dehub

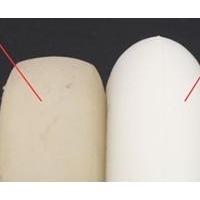

Underneath, you see a picture of two wheels. The left wheel, which is reasonably new, showing less than 30% wear and a completely new wheel (right wheel).

If the wheel looks reasonably new with less than 30% wear, and the urethane has clearly separated from the hub, then there might be a production error as shown on the picture below:

If the wheel shows more than 40% wear and the urethane is torn off or broken, but still attached to the hub, then it's often not a production error.

If you think there is a production error on your item, check our claim guide to see, what information to send us in order to start a claim.

Go back to Assembling a custom trick scooter

Go back to Stunt Scooters explained here.